Production

Product life cycle

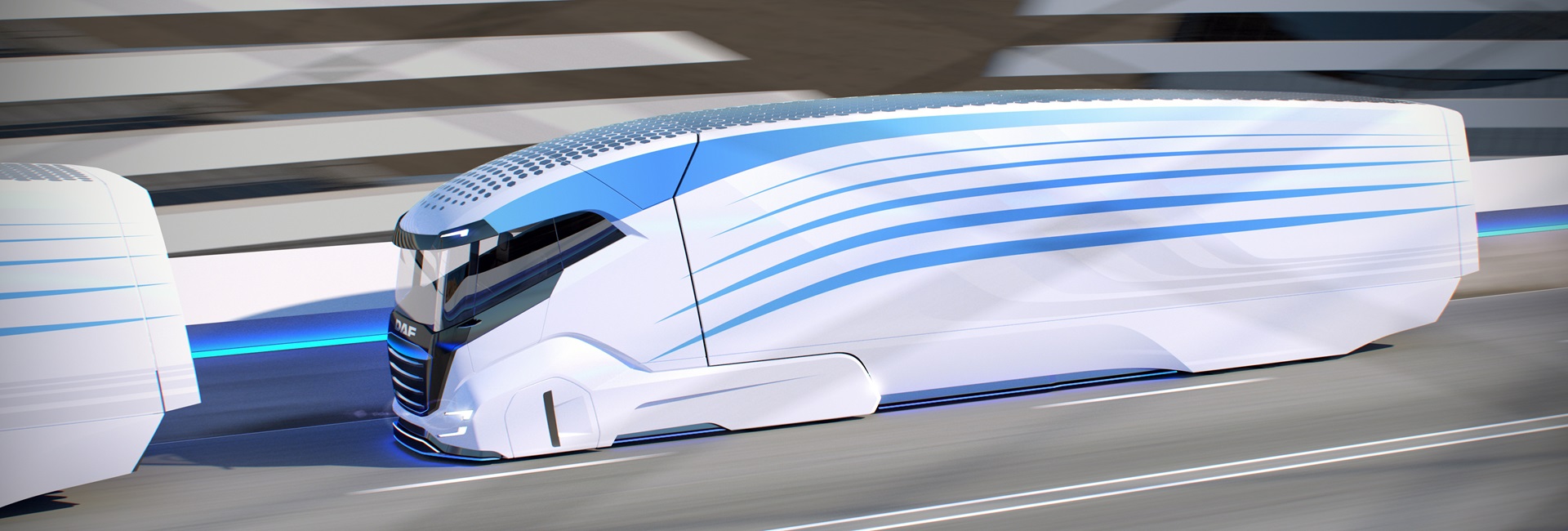

Product Development: EcoDesign

EcoDesign has been one of the focal points of DAF Product Development since 1998. This means that we not only look for solutions that are good for the environment but also those that improve the efficiency of the truck. Product engineers are trained in EcoDesign and during product and component development, they are required to identify technical opportunities to minimize environmental impact. To help them, they use an EcoDesign tool that specifies factors like recyclability of products, weight-reduction and how environmental aspects can be influenced in the production phase. In addition to product engineers, employees from Product Planning, Testing, Purchasing and Production are also involved in EcoDesign.

Limiting the impact of production processes

We aim to limit the environmental impact of our production processes by targeting the following aspects:

To reduce the environmental impact of our entire supply chain, DAF encourages suppliers to improve their environmental performance. Suppliers are required to hold a number of environmental certifications and comply with environmental legislation related to handling dangerous substances and recycling packaging material. We also expect suppliers to maintain ethical standards relating to employee safety, child labour and financial practices. Suppliers providing services on DAF premises must also meet strict environmental requirements. DAF rates its suppliers’ environmental performance through an annual ‘Vendor Rating Environment survey.