DAF in Action

Scrollytelling Slide new

More stories

Previous editions of DAF in Action magazine:

From idea to accessory

The DAF XD, XF, XG and XG+ set a new standard in the truck industry. And it goes without saying that the accessories for the ‘New Generation DAF’ must also be of the same high quality. So how does DAF go about developing its accessories? A quick look behind the scenes.

Many specialists were involved in the design, production, testing and fine-tuning of the accessories for the new XF, XG, XG+ and the brand new XD. It required product managers and designers at DAF to work closely together. For instance, the DAF Night Lock, DAF Cool Ultimate stand-alone air conditioner and the DAF Roof Bar involved many years of development because the completely new cabs and the various accessories had to match perfectly.

Premium look

DAF’s Design Director, Bart Van Lotringen, explains the process: “You can sum up the look that we give our new trucks in one word: ‘premium’. Of course, the same also applies to the DAF accessories that an owner or driver can add to make his or her truck even more personalised. A truck is an important business card for many of our customers and it’s part and parcel of their identity. They use it to stand out from the crowd and this is something we understand better than anyone else.”

“Before we even start developing a new accessory, we make a list of the requirements and options”

Jop Kerkhof,

Product Manager PACCAR Parts Europe

Functional and fine

Before we even start developing a new accessory, we make a list of the requirements and options,” continues Jop Kerkhof, Product Manager at PACCAR Parts. “What do our customers need and what do our dealers expect? Take the new Roof Bar. It has to be both functional and a decorative element of the truck, but there are other factors involved, too. For instance, what is a reasonable price, what materials can we choose from and how can we guarantee constant, premium quality? It is only when we have the answers to all of these questions that we put together a list of specifications which the design team can start working on.”

From paper to prototype

Suppliers then receive detailed CAD drawings which serve as a basis for an initial prototype on paper and then a working prototype. Kerkhof: “We literally test everything using a working model. For example, we look at how easy it is to assemble, whether the bracket design is watertight and how everything looks and ‘feels’ from on top of the cab. Of course, safety is also an important aspect. The Roof Bar needs to remain fixed to the cab under all conditions, and we know the extreme conditions under which our trucks sometimes have to work.” Van Lotringen continues: “When we say it is fixed, it really does mean fixed. We go to great lengths with our test programmes because we take the development of our accessories just as seriously as the development of our trucks. We simply have to be completely satisfied with the quality and safety of our products. We also place stringent demands on the ‘look’, as styling and functionality go hand in hand. Only then do we give the go-ahead to start making the final prototype.”

Scaling up to production

As Kerkhof explains, it can be months and even years before new DAF accessories eventually appear on the market. “Suppliers have to purchase materials, create welding jigs, design bending systems and sometimes even set up entire production lines. We all go on a long journey, from initial idea to final accessory. We occasionally face obstacles, detours and unexpected stop-offs along the way. But this is all justified by our final, common destination – everything has to be simply perfect. Always.”

Top 5 DAF accessoires

1. DAF Cool Ultimate, stand-alone air conditioner

2. DAF Night Lock

3. DAF Textile and Rubber Mats

4. DAF Roof Bar

5. DAF Microwave Oven

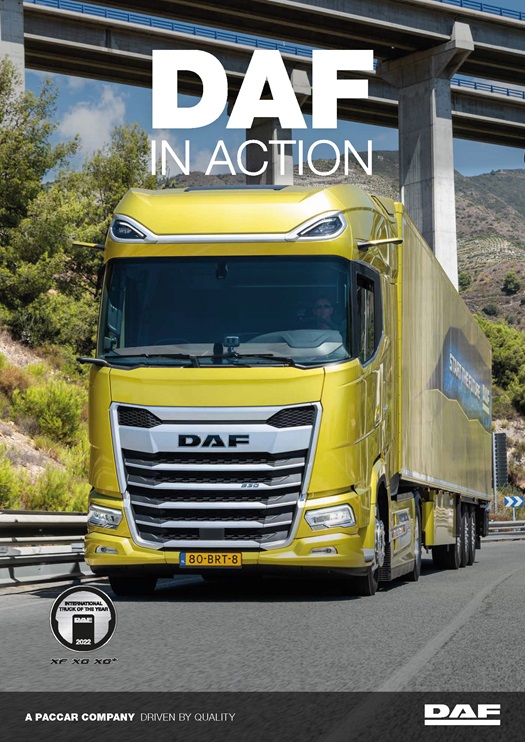

No ordinary yellow

The New Generation DAF, with its new XD, XF, XG and XG+ models, is the biggest design and development project in DAF’s history. So it’s only fitting that the new vehicles are shown off in a sparkling, striking and modern ‘Tuscan Yellow’.

“The launch colour is much more than just a colour – it’s a communication tool,” explains DAF designer Bart van Lotringen. “You want to stimulate interest in your new product and allow the quality to shine through in every brochure and every single promotional video. Naturally, customers can order their vehicles from us in any colour they like. We can offer them in 3,000 different colours, so practically every transport operator will be able to find their own company colour. However, around 70 per cent of our trucks are actually ordered in white, but we know that when people see our new trucks for the first time, the launch colour acts as an important trigger. The more striking the colour, the more attention the vehicle receives.”

DAF looked for a bright, high-quality colour to launch the new generation trucks.

The role played by colour

DAF uses paint developed by Axalta Coating Systems in Wuppertal. Elke Dirks has worked for the firm as an OEM colour designer since 1995. “People underestimate the role that colour plays,” she says. “Don’t forget that when we see a new product, the first thing we notice is its colour. This happens in a split second, and not just with vehicles but in fact with everything. It’s only afterwards that we notice the shape, the material its made from and the finish and function. A well-chosen colour has such a strong emotional resonance that colour influences 80 per cent of people’s buying decisions.”

Trends

“When Bart van Lotringen approached us, he explained how he was looking for a bright, high-quality colour to launch the new generation DAF,” recalls Martin Steinmüller, Colour Demand Manager at Axalta. “I didn’t have a specific colour in mind at the time,” Bart says. “That’s why we worked around the existing colours, so that we could see what would be aesthetically and technically feasible. Fortunately, we had Elke Dirks to help us, and she knows a great deal about industrial colour trends. This enabled us to rapidly whittle down the number of colours and focus our search.”

Martin Steinmüller,

Color Demand Manager bij Axalta.

Emotions

Elke Dirks: “People’s preferences for vehicle colours are constantly changing, so you have to follow these closely. It depends a lot on the spirit of the times and the group of customers, but new pigments also have a considerable influence. In the past, customers would say something like ‘just give me a sunny yellow’. These days, customers place more emphasis on their feel for a colour or a specific emotion. Which, in fact, is what Bart did too. The future launch colour for DAF had to exude positivity, quality, dynamism and power. That’s why we didn’t have a single colour at first but rather a number of bold, bright colours that we could work on.”

Preference for bright

“At DAF, we prefer bright promotional colours,” adds Bart van Lotringen. “The reason for this is that a truck cab has large vertical surfaces. Light reflects from these surfaces very differently when compared with the horizontal surfaces on a car, for instance. We wanted an exceptionally bright colour for the New Generation DAF. And that’s where Martin Steinmüller comes in, as it is not easy to mix a bright colour and get just the right amount of saturation. In the end, Martin mixed a dozen colours for us to choose from. We sprayed a few scale model trucks with the colours so that we could see exactly which ones would show off the contours of our new range to the full.”

No ordinary yellow

“Automotive colour design is just about different shades. You need to balance the interplay of effect, brightness and the pigments that are used,” explains Elke Dirks. “DAF trucks are impressive because of their wonderful aerodynamics and strong curves. These shapes also have an effect on the colour. If you get the choice of colour right, it will do even more justice to the design.” To illustrate this point, she flexes a sheet of steel that has been sprayed in Tuscan Yellow. “Can you see how the colour changes when I bend it? There’s an entire spectrum of yellow hues concealed in this Tuscan Yellow. It has a wonderful transition from light to dark and highlyaccented bright spots of light. It’s much more than just a yellow colour!”

“Automotive colour design is not just about different shades. You need to balance the interplay of effect, brightness and the pigments used”

Elke Dirks,

OEM colour designer

Flawless

Choosing a colour for a truck is one thing, but how do you make sure that the colour looks the same everywhere it is used? For Bart Lotringen, this was a real challenge. “You have to deal with each case individually. Naturally, we start with the actual truck, and the colour was spot on. The challenge then is to get our Tuscan Yellow to look the same everywhere in videos, in photos and in the brochure. It also has to look the same at an exhibition like the IAA Commercial Vehicles Show 2022 where our precious gems are on display under perfect lighting. We considered all of these factors when making our final choice for the promotional colour. And I’m very proud of our choice.”

Trends

Colour trends for trucks are often different from those for cars. “Over the last few years, the trend has mainly been for one of the ‘fifty shades of grey’ says Elke Dirks. “However, yellow is clearly becoming more popular and is a promising colour for the future.” Bart van Lotringen also sees something similar happening with trucks. “When we launched our new generation trucks last year in Tuscan Yellow, we saw how this amazing colour caught the imagination of transport operators. Since then, we’ve seen a doubling in the number of orders for yellow trucks.”

“The launch colour is more than just a colour – it’s a communication tool”

Bart van Lotringen:

Director Design

What exactly is Tuscan Yellow?

It’s not actually possible to reproduce the Tuscan Yellow launch colour for the new generation DAFs on paper. However, this colour is on the Pantone scale (PMS scale) used by printers all over the world. On the Pantone colour chart, this bright, egg-yolk colour is called ‘Tuscan Sun’. The Tuscan Yellow used on the new DAFs is much more than just a single shade, however. Depending on how the light falls on the vehicle, it is a constantly changing, living and reflecting symphony of colour.

“When I first saw the Tuscan Yellow colour swatch, it reminded me of a chrome metal surface,” Bart van Lotringen recalls. “I felt a thrill when I the this colour, it really is stimulating. Colour is pure emotion. However, I wasn’t able to describe this effect when I initially explained what I was looking for. In this sense, it has truly exceeded my expectations.”

DAF confirms its leading position in clean transport with the XD and XF Electric

DAF Trucks will start production of the first all-electric versions of its New Generation DAF XD and XF in early 2023. DAF is giving transport operators the choice of a completely new series with modular powertrains that boast power outputs of between 170 and 350 kW. The vehicles can handle a range exceeding 500 km, depending on the battery pack, all on a single charge.

By: Bert Roozendaal

DAF Trucks has once again confirmed its position as the leader in the field of clean, ‘zero-emission’ road transport. In 2018, DAF was the first truck manufacturer in Europe to offer a fully electric distribution truck. The company went on to sell dozens of its BEV CF Electric tractor units and box trucks to transport operators who wished to join DAF in taking the lead in zero-emission transport.

Taking Electric transport to the next level

DAF is bringing all-electric road transport one step closer with its latest generation of BEV vehicles. Transport operators have a wealth of options to choose from, as DAF now covers their transport needs with two completely new electric motors and five different power classes that offer ranges of between 200 and over 500 kilometres without the need for recharging.

It means that every transport operator can precisely configure their BEV vehicle to optimally suit their specific application. The new DAF programme of electric vehicles starts with the New Generation XD Electric 170e, which is equipped with a new PACCAR EX-D1 permanent magnet e-motor with an output of 170 kW (230 hp). Its energy comes from a battery pack comprising two cells as standard, which provides a total output of 210 kWh and gives it a range of 200 ‘zero-emission’ kilometres. This makes the XD 170e perfect for city distribution and waste collection over short and medium distances, particularly when the driver is able to recharge during a break or while loading or unloading goods.

The PACCAR EX-D1 e-motor is also available for the DAF XD, with power outputs of 220 kW (300 hp) and 270 kW (370 hp) combined with a battery pack containing a cluster of three cells that provides a range of 300 ‘zero-emission’ kilometres. Transport operators can also opt for a five-cell battery pack and enjoy a maximum range in excess of 500 kilometres, all on a single charge.

For more heavy-duty work, DAF will be supplying both the XD and the XF with the new PACCAR EX-D2 power unit from 2023. This electric motor delivers even higher power outputs: 270 kW (370 hp), 310 kW (420 hp) and even 350 kW (480 hp). The most powerful versions come with four battery cells as standard that give the vehicle a ‘zero-emission’ range of over 400 kilometres, depending on the conditions and application. A five-cell pack is also available as an optional extra.

The new DAF XD and XF vehicles are available with a wide range of e-motors and battery packs, which make all-electric ranges from 200 to over 500 kilometres a reality and enables DAF to provide a solution for every ‘zero- emission’ application.

International

Alongside having the largest battery pack, the more powerful PACCAR EX-D2 e-motor also enables ranges in excess of 500 kilometres on a single charge, depending on conditions. In one full swoop, international all-electric road transport becomes possible. Smart planning and recharging make it possible to cover over 1,000 fully electric kilometres each day. This is more than sufficient, as no driver is capable of covering more within the 10-hour legal driving limit.

Lightning-fast charging

DAF has also made further improvements to the charging and recharging of the new generation XD and XF Electric using rapid AC (alternating current) charging technology. This enables a flat three-cell battery pack, for instance, to be charged up to 80% in the space of 45 minutes. It means that transport operators can now offer fully electric services between regions. Incidentally, the DAF Electric can also be charged using direct current at 22 kW, as an optional extra, which provides greater flexibility in areas where rapid-charging infrastructure is unavailable.

Bodybuilding versatility

All truck manufacturers face the challenge of where to fit the battery packs without them getting in the way of the truck’s body. DAF’s answer is to make intelligent use of the available space. With the New Generation DAF, it is possible to link the batteries together in modules that make a variety of layout configurations possible. As a result, the new XF and XF Electric are just as versatile when it comes to bodybuilding as the existing models in the New Generation DAF range. They also have space for a side-loader body and support legs, and an electrically powered PTO is also available.

Subtle distincion

The electric models of the new DAF XD and XF naturally have the same attractive exterior design as the diesel-powered versions. However, they also have some subtle differences, so you know straight away when you’re looking at a completely zero-emission vehicle. For instance, the New Generation BEV vehicles have subtle blue details on the grille and headlights and a slightly different digital dashboard configuration. This enables the driver to see the vehicle’s consumption in kW and the remaining driving range. The optional navigation system on the XD and XF Electric even shows the locations of public charging stations.

DAF provides charging infrastructure

One way that DAF clearly stands out is by providing transport operators with a full range of charging solutions, including an extensive range of mobile and fixed PACCAR charging stations that have been specially tailored to match the new XD and XF models. And these charging stations can also be used for the current electric CF and LF models, delivery vans and even cars. Depending on the individual site, the PACCAR stations can deliver power outputs of up to 350 kW for ultra-fast charging. DAF also supports its customers by providing personalised sales advice with advanced route simulation models so that they can seamlessly switch to e-trucks with zero emissions.

Available to order now

If you want to start driving a new XD or XF Electric next year, they are available to order now. The vehicles can also be ordered with different axle configurations and cab variants. It is clear that with the new DAF XD and XF Electric vehicles, DAF continues to build on its leading position in zero emission road transport.

Keeping it in the family

Ted Hughes is the director of Hughcor, a transport operator based in South Africa. He recently bought his first DAF, an XF 480 Space Cab, which brought back fond memories of the 1980s for him and his daughter Siobhan.

Hughes started his own transport firm in the United Kingdom back in 1968 with a single tipper. His business boomed and within a short time he was operating ten semi-trailer trucks across Europe. When he emigrated to South Africa in 1980, he worked as a driver for three and a half years at Swift Transport in neighbouring Zimbabwe. “It was a huge learning experience,” he explains. “I needed it, too, as the difference between road transport in South Africa and Europe was and still is enormous.”

Dedicated

After working for various other transport operators, Ted Hughes set up his own firm again in January 2008. His company, Hughcor, has gone from strength to strength and has become a successful medium-sized haulage firm that specialises in long distance transport. Although he is now over 75, he’s still keenly involved in the daily comings and goings at the family firm. In fact, he has so much vigour that he continues to work six days a week. “This industry is all about passion,” he says. “You don’t get very far without passion.”

Siobhan is also actively involved in the company and has been crazy about trucks since she was ten.

Mrs Hughes

‘Family firm’ is a phrase that crops up again and again. Hughcor’s success can be largely attributed to Mrs Hughes, who is the firm’s Operations Manager. “Ruth is the driving force behind our company,” says Ted, visibly proud. “She works incredibly hard to win orders and makes sure that all our customers’ goods arrive safely and on time.”

Daughter

Their daughter, Siobhan, is also actively involved in the company and has been crazy about trucks since she was ten. “She used to come on the road with me during her school holidays,” Ted explains. “She’d sit in the passenger seat with a book or lie behind me in the bed and read. She’d also make me coffee and snacks while I was behind the wheel.” For someone who spent such little time at home, those days on the road with his daughter are cherished memories for Ted.

Studies

When she finished school, Siobhan decided to work at Hughcor too, where she now looks after the accounts, human resources and the logging of diesel consumption. “She has more than earned her stripes in the transport world,” according to Ted Hughes. When the new DAF pulled up at Hughcor’s site, his daughter immediately climbed in behind the wheel, bringing back memories from 25 years ago when she would lean out of the window of her dad’s old DAF.

When the new DAF pulled up at Hughcor’s site, his daughter immediately climbed in behind the wheel, bringing back memories from 25 years ago when she would lean out of the window of her dad’s old DAF.

Torque

Hughes has been driving DAFs since 1985 and has always been impressed by the performance of these Dutch trucks. The torque on his previous DAF 95 with 430 hp (no slouch in those days) obviously doesn’t match that of his new DAF. “I still managed to overtake many of my competitors those days, even going up the steep Van Reenen Pass,” he remembers. “And with a full 50-ton semi-trailer behind me, too. Of course, my new DAF is much more impressive.”

Uphill

“Although trucks are not allowed to drive over 80 kilometres per hour in South Africa, you have be able to pick up speed uphill and decelerate safely down the other side,” explains Hughes. “Older trucks are often unable to do more than 10-15 kilometres per hour uphill, but we easily hit 50 km/h in this new one. It means our average speed goes up and that saves time.”

Satisfied

In addition to the performance and fuel consumption of his new DAF, Ted is extremely satisfied with the service he receives for his vehicle by the importer, Babcock. “Together with DAF, they complete the picture. It’s safe to say that we’ll be buying more DAFs in the future.”

When are we going to see next-gen shipping containers?

Erwin Rademaker, Programme Manager at the Port of Rotterdam, knows that around 85% of all cargo is transported by container. This makes the shipping container one of the most standardised elements in the global logistics chain. But this is 2022, so isn’t there a way to make the container a little smarter? The Port Of Rotterdam Authority intends to find out.

By: Bert Roozendaal

The invention of the shipping container in 1955 by Malcolm P. McLean and the almost simultaneous introduction of the twist-lock mechanism by Keith Tantlinger at Fruehauf saw these two men spark a veritable revolution in the transportation world. There are currently around 30 million containers circulating around the world, and this number is only set to increase.

Gigantic

A shipping container offers huge efficiency gains, but after 65 years its shine is beginning to wane a little. Despite all the smart technology that the logistics sector is embracing these days, this amazing watertight container with its standardised dimensions is still the most rudimentary link in the entire chain.

Sending the shipping container across the world enables us to collect data.

Deafening Silence

Whereas transport firms and shippers are increasingly able to monitor equipment and shipments transported by trailer while they are on the move, they often still face a deafening silence from the containers themselves. When a load is destined for somewhere in the hinterlands of China or South America, we only know whether everything is still intact, has survived the journey, has been tampered with along the way or had something added to it when it reaches its final destination. The container still also needs to be accompanied by a considerable paper trail, electronic or otherwise, as a container passes from one shipper to another over the course of its journey, all of whom bill their costs separately.

Smarter

Rademaker’s ideas on how to make containers smarter have to do with the Port Authority’s own aspiration to become ‘smarter’. “We expect to see the first unmanned commercial ships berthing at our quays in the next couple of years. This will mean that the container cargos on those ships will also have more sophisticated IT systems.” This is because the container itself can contribute to the way in which it is handled. “For instance, the container can report its contents and the condition of those contents in advance. What if in the near future a container had a type of e-wallet that allowed it to immediately settle all of its own handling costs? It would be able to inform the loader and the recipient that it is being moved onto a train, waiting somewhere or even that it is being opened illicitly. Just about anything is possible.”

Around 85 per cent of all cargo is transported by container.

Container 42

Rademaker has already put his vision into practice in his ‘Container 42’. This shipping container is packed with instruments, sensors and track & trace systems for research purposes and its doors are fitted with sturdy mortise locks. It also contains a ‘load’. “By sending the container all over the world we’re able to learn about the continuity of the journey. It allows us to gather data, for instance, on the temperature, humidity, jolts, angle of inclination of the container and much more. We also want to find out how the instruments bear up on the road and the requirements they will need to meet.”

The answer is 42

The number ‘42’ doesn’t refer to the size of the container but rather to a sci-fi book by Douglas Adams in which a computer predicts, after 7.5 million years, that the universal answer to everything is 42. “We don’t want it to take that long, of course,” laughs Rademaker, “and our container is not the universal answer to everything. But I do think that with an upgrade costing around 1,000 euros per unit shipping containers will be able to play a much smarter role in transport over the coming years. That may sound like a huge amount for 30 million containers but it’s peanuts on a global scale. It doesn’t all have to be done in one go, either. We already have a global transportation unit. Now all we need to do is take it to level 2.0.”

“Top of our wish list”

STL Logistik AG, based in Haiger in Germany, is a leading name in Europe for heavy-duty and special transport. Last year the company bought three DAF XG+ tractor units ‘sight unseen’. STL was so pleased with them that it immediately placed an order for another six.

Text: Oliver Willms

Photography: Steffen Löffler

Owner/managing director Jörg Reichmann knows all about extremely heavy and oversized loads and how they behave during transport. It’s not without reason that his company has a solid reputation in the German federal state of Hessen. That’s because over the last 28 years it has been the first port of call for the long-established coal and steel industry and all the suppliers based here. Whenever they need to transport a large, heavy, high or wide load, they turn to his company. Reichmann’s clientele includes boiler and silo manufacturers, firms specialised in metal pressing and manufacturers of huge steel rings. These types of products often have diameters of over five metres and do not fit easily onto a standard semi-trailer.

Leader in transporting tilted loads

Reichmann got together with local trailer specialists to develop a special low loader for transporting oversized components at an angle using hydraulic mechanisms. This is how STL is able to transport many components for large installations and ensure that the outer dimensions remain within the legal limits. “Our innovative engineering enables us to offer our customers tomorrow’s transportation technology today”, says Reichmann, confirming his company’s leading position in the field. Although competitors are not sitting back idly and have also started to transport tilted loads, STL is still considered the leader by European industries when it comes to transporting these kinds of exceptional loads.

Ten years with DAF

In addition to flat loaders with three hydraulic loading tables that can be tilted into a diagonal position, STL also operates curtainsiders that can be extended up to 28 metres and a variety of low-loaders with lengths ranging from 8 to 27 metres. It also deploys flatbed semi-trailers and telescopic flatbed trailers that can be extended up to 29 metres. For more ‘run of the mill’ work, STL uses mega trailers and also tautliners and flatbed trailers. STL operates around 140 trailer units which are attached to tractor units starting with a range of standard 480 hp 4x2 tractors. Some of these use a low-deck configuration. For demanding work, STL uses more powerful vehicles in 6x2, 6x4 and 8x4 configurations and the majority of these are DAFs. Reichmann has been a regular DAF customer for over 10 years through his local DAF dealer in Siegeb. Half of the trucks in STL’s carefully maintained fleet is DAFs. None of its 105 tractor units is more than four years old and the majority of the DAFs are top-of-the-range XF tractor units. Last October, STL brought its 50th DAF vehicle into operation – a 530 hp XF FTG 6x2 – with all the requisite fanfare.

“We have created our own drivers’ academy.”

Jörg Reichmann,

Owner / managing director STL Logistik AG

New horizons

This vehicle was the company’s showpiece for a couple of months, but for three drivers at STL the bar has since been raised even further in terms of space, luxury, comfort and safety. That’s because a couple of months ago three DAF XG+ tractor units joined STL’s fleet. And Reichmann did not skimp on the optional extras. On top of the many standard features – all guaranteed to get drivers’ hearts racing – the new trucks were also equipped with optional extras such as a stand-alone air conditioner, swivel driver’s seat and electrically adjustable relax bed. In fact, STL was so impressed with the New Generation DAF that it ordered another six straight away.

Brochure

“We ordered our first DAF XG+ on the basis of the brochure alone”, revealed fleet manager Thomas Schubert-Wirth. “No one in Germany had even seen the New Generation DAF up close, let alone driven one. But we were swayed by the design and DAF’s consistent implementation of the latest EU directive for new truck cabs and vehicle dimensions.”

“The DAF XG+ is not only a big hit with drivers because of its high roof and unique 12.5 cubic metre work and living space, it’s a winner in all areas.”

Thomas Schubert-Wirth,

Fleet Manager

Brave move

It was a brave move, but it paid off in the end. STL Logistik was one of the first companies in Germany to operate DAF XG+ vehicles in its company colours. “At first we were concerned about whether the unloaded weight of such a large cab would have a negative effect on the vehicle’s overall load capacity compared to the previous XF. But in fact the opposite turned out to be true. Even though the cab is 49 centimetres longer and has a higher roof and larger wheel base, it actually weighs around 150 kilos less! We were so amazed by this that we immediately ordered more XG+ trucks.” In addition to the lower operating costs, STL also sees a chance to win over the hearts and minds of its drivers. “They’re all crazy about the new DAF” says Schubert-Wirth. “The XG+ is not only a big hit with drivers because of its high roof and unique 12.5 cubic metre work and living space, it’s a winner in all areas.”

“DAFs have always been good, but the new DAF XG+ takes things to another level”.

Jan Halmann,

STL-driver

‘Simply magnificent!’

STL driver Jan Halmann is convinced, in any case: “DAFs have always been good, but the new DAF XG+ takes things to another level”. The 36-year old driver was among the first to get his hands on the flagship model from the Netherlands and he is wildly enthusiastic about it. “It’s extremely spacious, nothing else comes close to it.” For Jan, “drivers have never had it so good. I think it’s simply magnificent! And the digital dashboard, it’s light years ahead of its predecessor. But one thing has stayed the same. Everything is still intuitive and really easy and safe to operate.” Jan Halmann is also enthusiastic about how his new truck drives. “It handles the same on every road surface and cornering is silky smooth. It’s even quieter than the previous model”, he says, full of praise for ‘his DAF’. “And the 80 cm, electrically adjusted, multi-position relax bed with the wide mattress is more comfortable than my bed at home. Another thing I appreciate is the new Corner Eye. The camera gives you an incredibly clear and wide view of what’s going on at the front and side of the truck. It makes my work a whole lot safer.”

Uptime

Like most of his colleagues, Jan Halmann not only drives all over Germany, but also France, Spain, Denmark, Poland and Slovakia. Despite this, he only clocks up an average of 120,000 kilometres a year with STL, which is not exceptionally high. As STL places a high value on getting the most uptime out of its trucks, it has full-service contracts to cover all the maintenance and repair of the vehicles over their lifespan. STL’s workshop mainly takes care of the maintenance on the trailers and minor repairs to the trucks but the company finds it is best to get the trucks serviced by an authorised DAF dealer.

Drivers are our future

In common with many other companies in the road transport sector, STL is also facing a dire shortage of drivers. “That’s why we have created our own drivers’ academy and we offer bursaries to recruit and retain staff”, explains owner Reichmann. “But you also have to offer them something else as well. This is where the new DAF XG+ is going to play an important role, as I am sure that it is at the top of many drivers’ wish lists.”

“Setting the standard for international transport”

The new DAF XG+ proved itself the rightful holder of the International Truck of the Year 2022 title during a 2,500 kilometre test drive from Malaga to Eindhoven.

Text: Oliver Willms

Photography: Andreas Techel

It’s been a long time since we last saw a truck as innovative as the new DAF XF/XG/XG+. DAF is the first – and so far the only truck manufacturer – to implement the new EU regulations on dimensions and weights. This was a huge move, which was evident even during the initial presentations. Alongside the design, DAF has also improved the technology to the highest level and the quality of the interior ranks among the very best in the premium segment.

Milestone

That’s all well and good, but we don’t look at the truck. We want to drive it, experience it, live in it and see how it performs under real-life conditions. DAF wants to show us the road to the future with its new flagship model. We say bring it on, but preferably without the comparison figures, test diagrams and torque specs. We want to put the “new one” through its paces and experience it to the full. And what better route could there be than the ultimate endurance test from Malaga to Eindhoven? It cuts straight across Europe with mountain stages in the Sierra Nevada and the Belgian Ardennes, weaves through rush hour traffic in Madrid, Paris and Brussels, skims along secondary coastal roads beside the Atlantic Ocean and winds through the almost unfathomable and endless maze of Antwerp’s docks. This truck is different. It represents a milestone and you see it immediately. The minute you step up into the cab, that feeling only gets stronger.

“Late in the afternoon, the DAF guzzled some real atlantic sea air through its air intake”.Oliver Willms is a freelance journalist for various German trade journals and is also a member of the ‘International Truck of the Year’ jury on behalf of Germany.

Tiny house

You can neatly sum up the new DAF XG+ in: big! Not only does the truck look impressive on the outside, but the cab on DAF’s new top model actually towers over the Super Space Cab. That cab used to be European champion with regard to usable inside space, but now the XG+ shows that it is possible to have even more space. It’s gone from being a workplace to a living room. The cabin is almost a Tiny House in itself, or even a prestigious motor home for international transport. You will not find a more spacious cab! It boasts a capacity of twelve cubic metres, making it DAF’s largest cab ever.

The seating position is so comfy, it’s as if you’re lounging at home in your favourite armchair and everything you need for driving is within easy reach. The incredibly wide windscreen not only neatly curves around the A pillars and has a low drag coefficient, but the low window belt line also gives you an exceptionally good view of the road ahead. Despite its enormous viewing angles, the design also provides sufficient privacy from the curious gazes of other truck drivers. And we did attract a lot of attention from other drivers on the road. The comfortably thick, leather-lined steering wheel can be easily adjusted to suit any body size, including mine, thanks to its wide adjustment angles. So, with a quick turn of the ignition key, we started our journey to the future. The first thing we notice is that the engine has that same soft and subtle purr of a coach engine. But a coach engine is mounted a good 12 metres behind the driver in the engine compartment.

The buttons on the steering wheel prevent you end up with greasy fingermarks on the touchscreen while you’re driving.

Engine compartment

The engine on our DAF is under the floor, but you barely see more of the engine compartment than a raised section in the middle of the floor that is a mere five centimetres high. The 480 hp, six-cylinder MX-13 engine delivers 2,500 Nm of torque and promises more than enough pulling power, a feature that this beauty got the chance to demonstrate in the Sierra Nevada, where the Spanish Autopista is famously not lacking in long, steep gradients that dragged even our powerful XG+ below 60 km/h on occasion. But there’s no shame in that as we were carrying a total weight of 40 tons. And also because the engine manages the climbs with aplomb and the Predictive Cruise Control worked in perfect harmony with the 12-speed Traxon automated gearbox.

Smooth

This all means that we can focus our attention fully on the real reason why we are behind the wheel, concentrate on the road ahead and get on with the actual driving, all the while enjoying the amazing mountain landscape of Spain’s Sierra Nevada, which proves to be the first of many memorable moments. This DAF is a truck that you’ll fall in love with. The fully hydraulic power steering guides the 40-ton truck smoothly and with razor-sharp precision over the Andalusian slopes. There’s no need to apply any more force to the steering wheel than you would with an electro-hydraulic system. It hits the sweet spot with perfect precision.

A picturesque parking spot next to an historic warehouse at the Port of Antwerp.

Powerful engine brake

The same is true for the new MX engine brake. We certainly put this to the test, as the steep Spanish ascents gracefully change into equally steep descents. When the DAF’s impressive 500 hp braking force kicks in, we feel the engine brake effortlessly handle the descent. There is absolutely no need for a retarder on this DAF. The pulling power on the ascents and the braking force on the descents turn our trip through the mountain foothills of Southern Spain into a real treat. This is put sharply into perspective when we see how other truck drivers struggle, not infrequently, to keep up with us. They are only able to muster a raised thumb as a token of their enthusiasm. We see lots more raised thumbs even as we travel uphill and effortlessly overtake other trucks, which is a pleasing sight. However, it feels a little undeserved as the homage paid by our fellow drivers to this masterpiece on wheels is all down to the engineers at DAF.

Highly adjustable

The XG+ is also a snug workplace for taller or more heavyset drivers. It’s possible to move the seat back to what appears to be the middle of the trailer. You can adjust the new steering column to almost any position, from horizontal, like on a Routemaster, to upright à la Ferrari. The control stalk for the windscreen wipers and the engine brake are where you would expect them to be and the buttons on the steering wheel prevent you end up with greasy fingermarks on the touch screen while you’re driving. It’s basically every driver’s dream as a workplace. The view through the panoramic windscreen makes you feel like you’re at the cinema and, as a DAF driver, you always have the best seat. A magnificent silver screen!

Digital mirrors

Since everything on the outside of the XG+ is about maintaining the consistency of the aerodynamics, digital mirrors are essential. The camera system is given a baptism of fire in the mountains with the rapid changes from sun-drenched motorways to mountain tunnels. It certainly does not disappoint. Quite the contrary, in fact! On the slimline displays mounted flush to the A pillar we see the system adapt sharply to the changes in light and dark in a split second. The rear view, in what are often sparsely-lit tunnels, is clearly among the best on the market. You can see so much more with these camera mirrors than you do with regular mirrors, as the electronics beautifully enhance the image. This is also true in twilight and even when it is pitch black outside; the displays perform just as well as a regular mirror.

Violins

With the many tunnels through the mountain foothills now behind our Tuscan Yellow express train, the blurred lights of Madrid emerge in the distance and guide us to our first stop-off point. It is getting late and the sun is sinking below the horizon. The powerful beams of the new LED headlights are a valuable addition to our safety on the road. We park up around midnight to get a few hours’ rest in the new DAF beds. As I lie in my bunk and look upwards, I can see the sky a good 220 cm above the floor. I almost expect to hear the swell of violins echoing around this huge space. That doesn’t happen, of course, but it’s clear that the storage space of the XG+ cab, just like its predecessor, the Super Space Cab, is a bottomless pit. Luggage, provisions and anything else that two drivers tend to lug along with them on a long distance journey all effortlessly disappear into one of the many compartments on board. When you add the swivel seats and the famous tray that slides out from the dashboard, this spacious cab has almost the same level of comfort that you’d find in an apartment. All that’s missing is a shower cubicle.

Like the back of his hand

Although I get a good night’s rest on the 15-centimetre - thick comfort mattress and appreciate the fresh stand-alone air conditioner, the next morning comes around sooner that I’d have liked and we have to continue our journey. Our schedule is tight, and alongside an hour of visits from fellow drivers at various truck stops, we also have to do a photo and video shoot. It is late in the afternoon when the DAF finally gets to guzzle some real Atlantic sea air through its air intake. We then put it through a handling test on several kilometres of narrow coastal roads near a Basque surfing hotspot. Both the cabin experience and the drivetrain pass with flying colours and when we reach the end of the winding road with a sea view we swap experiences over coffee a few other fellow drivers. Mahmud has sworn by his DAF XF for years and knows the route from Southern Spain to the Benelux region like the back of his hand. However, no matter how many tips he is able to give us, we see that his eyes are constantly being drawn to our new DAF. After giving him a guided tour, we know for sure that this French driver will soon be having an urgent talk with his fleet manager.

Chassis test

After this exciting excursion along a narrow coastal road, we head back to the motorway and onwards to the French border. The pitiful state of the road surface conveniently allows us to test the configuration of the chassis. Just as we expected, the springs and shock absorbers cope effortlessly with the torture mercilessly meted out on us by the Spanish government. Satisfied with the result, this is another element we can tick off in favour of the DAF. It is becoming increasing clear that it is going to be difficult for us to find any faults at all with the DAF. Ok, perhaps the engine brake warning light is a little small. It is only a minor niggle, as even without a light you can feel it working well. It is also possible that anyone tempted to lounge back into their seat due to the generous steering adjustments may not be able to see all the switches. But this is something the driver can control and you can always choose a more active seating position.

No unnecessary frills

Something else that catches our attention is that this sturdy DAF is not crammed with every additional extra under the sun, which usually have more to do with marketing than the actual driver. You won’t find any overengineering, but rather everything that a driver needs and could ever want. We think it strikes a very good balance between what you control with the touch screen on the central display and what you control with the buttons, in particular those on the steering wheel. The motto is ‘keep your hands on the wheel and your eyes on the road’. The rest is just choice overload. And if you’re not sure whether to opt for the electronically controlled parking brake or the trusty pneumatic handle, with DAF you can have both.

Champions league

It’s clear to us that the new DAF is in the Champions League of European trucks. Although it’s more expensive than it predecessors, it also boasts the highest quality and is better than ever. It hasn’t gained any extra pounds either, despite its increased bulk and the high level of finish that we come to appreciate more and more as our three-day tour progresses. We are constantly discovering new things and seeing the vehicle from new angles. For instance, lines projected onto the mirror display help you to properly manoeuvre or overtake, and the cameras also pan around corners. The panoramic windscreen provides an excellent view of the road and the blind-spot assistant works as it should and increases safety considerably. However, DAF’s greatest virtue is the constant attention it pays to the driver. XG drivers can always sit in a relaxed and healthy position behind the wheel and are spoilt for choice when it comes to seat adjustment. Naturally, there are limits, and for understandable reasons you can’t move the handle on the swivel seat while you’re driving. If you do, you’ll be bombarded with a series of ear-piercing beeps that force you to be more disciplined behind the wheel. Apart from this acoustic warning, the new DAF is incredibly silent. Surprisingly so, even when driving at top speed along a motorway with the window open. The aerodynamic curves of the windscreen mean you don’t hear much more than a gentle whoosh. A welcome side effect of this, thanks to the aerodynamics which have improved by 20 per cent, is that the side windows stay clear even in bad weather. DAF has also reduced air drag all around the vehicle, from the roof to the bumper, by sealing crevices and seams and by fitting the right spoilers with elasticated rubber lips in the right places. This is why there are no more step plates at the front of the truck. DAF now supplies a rod with a brush head for cleaning the windscreen.

At the end of a winding road with a sea view, we swap experiences with a few other drivers.

Stopover

We have another early start the following day. After the first stretch of motorway and an eye-opening stopover at one of those new mega truck stops, it becomes clear that the romantic and traditional ‘Relais’ restaurant of the past has made way for a more commercial type of establishment. Here the food is neither cheap nor tasty, and the atmosphere is anonymous and sterile. We decide to take a shortcut along the Route Nationale. This toll-free road is almost as smooth as a motorway but generally offers much more pleasant views. We come across a recently closed Relais that sparks our curiosity. We take a few photos and then switch seats again. Soon enough we make our next discovery on this route: a sprawling truck parking facility in the middle of a forest that is completely free of charge! The trucks parked under pine trees as tall as church towers make it look like a magical forest for drivers. The adjoining petrol station is just a few hundred metres away and serves up the next highlight of our trip. The tiny shop is chockfull of all kinds of accessories, and its manager is a diehard diesel-head. The trucking scene is still alive and kicking here! These kinds of stopovers are terrific but take up valuable time, and we need to burn some more rubber to avoid the ban on trucks around Paris on Saturdays. DAF and driver have been fused into a single driving machine. We can trust the vehicle unconditionally and can see that it has been designed with the driver in mind.

Belgian fries

Sometimes things go your way. The next morning we don’t meet any traffic jams on our journey around Paris. We have our hearts set on a jumbo bag of Belgian fries but our hopes of tucking into a cone of Belgium’s finest are soon dashed at Antwerp’s oil port, as we become the victims of our own self-imposed tight schedule. Things then go from bad to worse. At a picturesque parking spot next to an historic warehouse, we even have to go without breakfast. The other drivers parked there are extremely curious about our yellow DAF. We are a welcome distraction in their compulsory rest period and they are soon sharing shared our enthusiasm for the truck. However, the XG+ has clearly picked up the scent of its stable, now a mere 90 kilometres away. We admire the precision steering once again on the roundabouts at the port, and after a short stretch of motorway, we arrive at the entrance gate to the DAF factory in Eindhoven. Incidentally, this gate is almost the same width as the toll booths in France. The gate supervisor smiles when we toot our horn and after 2,485 kilometres we park our elegant yellow fortress, without a single scratch, at the DAF factory. As we step out of the cab, we are brimming with new ideas. Our conclusions will not come as any surprise. The DAF XG+ combines a proven drivetrain with a brilliant engine brake in a cab that has an unprecedented amount of interior space. On top of this, the fuel economy is outstanding. Even with our robust style of driving, by the time we arrive home we have only consumed around 24 litres per hundred kilometres. In other words: ‘Mission Future’ has been successfully completed.

The future looks bright!

It is with great pride that we – on behalf of over 10,000 of our enthusiastic colleagues – present to you the new XD and XDC in this edition of DAF in Action. A series of trucks that will set new standards in safety, efficiency and driver comfort in the distribution and construction segment. That was also the verdict of jury for the International Truck of the Year, who awarded the XD with the prestigious title ‘International Truck of the Year 2023’.

The new XD shares the same DNA as our top long distance models, de XF, XG and XG+, who received the International Truck of the Year award last year. An equally attractive and aerodynamic design. Unrivalled interior space in the cab and a premium finish. Fantastic driving qualities. Extremely efficient drivelines, including a fully electric version.

All that makes the XD much more than a perfect truck for distribution, the construction industry and more specific applications, such as garbage collection and fire-fighting. The XD also illustrates DAF’s leading position in the area of alternative drivelines. With a choice from a wide range of e-motors and battery packs, not to mention a comprehensive service package for these ‘zero-emission’ trucks.

Route simulations help you to decide on the perfect configuration and optimal application for your truck. And the PACCAR charging stations offer an unmatched degree of flexibility.

Leading the way towards a cleaner and brighter future!

Harald Seidel

President

DAF Trucks N.V.

DAF introduces the new XD and XDC

The IAA in Hannover - Europe’s leading commercial vehicle exhibition. DAF announces expansion of its ‘New Generation DAF family’ and causes a stir in the market with its all new XD and XDC models. Everyone agrees: “This is the most desirable distribution and construction truck in the market.”

By: Bert Roozendaal

It almost appears to be an undeniable fact: the New Generation XD will literally change the face of the distribution market and boost DAF’s image as a premium brand. Especially because DAF is the first truck brand to implement the latest EU regulations on larger dimensions in a truck that is safer all round, provides better fuel economy and offers incredible comfort for drivers. This is literally the birth of a new class.

More options

The DAF XD is available with a Day Cab, Sleeper Cab and a Sleeper High Cab in a full range of 4x2 and 6x2 axle configurations as both tractor units and rigids. In early 2023, the range will be expanded further, including 2-, 3- and 4-axle models with single or double drive for the construction industry (see sidebar). Then, DAF will also begin production of the XD model as a ‘Battery Electric Vehicle’. These zero-emission vehicles have electric motors ranging from 170 kW to 350 kW and battery packs with power outputs up to 525 kW/h. Depending on the application, ranges of 200 to over 500 kilometres will become within reach. This is sufficient for a full day’s distribution work without the need for intermediate recharging.

The New Generation DAF XD literally changes the face of the distribution and construction market.

Bigger

In terms of design, the new DAF XD shares many of its styling elements with the new XF, XG and XG+ for long haul – the ‘International Trucks of the Year 2022’. This means it has an attractive, friendly and extremely aerodynamic design, and last but not least, plenty of interior space. A vast amount of interior space, in fact, which is so valuable to drivers in the distribution sector. The new Day Cab already makes a wonderful impression with drivers. It even has space behind the seats for an optional fridge or a third seat directly fitted at the factory! Furthermore, the XD measures 2.5 metres in width, making it just as wide as its larger siblings.

Superb accessibility

The cab is mounted low on the chassis so it is extremely easy to access using only two steps in most cases, and the steps also lean in towards the cab. Another smart feature is the low engine tunnel which houses the hypermodern and efficient PACCAR MX 11 engine. It delivers a power of between 220 kW/300 hp and 330 kW/450 hp and is connected as standard to a TraXon automated gearbox for maximum efficiency and driving comfort. A fully automatic transmission is also available as an optional extra.

Superior comfort

The spaciousness of the cab means that the driver has more room behind the wheel than ever before. The ranges for adjusting the steering wheel and seat are the best in the entire distribution segment and add to the superior level of comfort that DAF offers to distribution drivers. There are many other examples: the entirely new dashboard with its large, central LCD screen, the blissful beds that boast a 15 cm mattress, the extensive storage options and numerous pockets, and also the many smartphone charging sockets, to name just a few. A high-end audio system with woofer and an electronic parking brake are available as an option.

The XD exudes comfort and sets a new benchmark in this regard too. It also goes without saying that the ride quality and steering are second to none. Thanks to the completely new design of the front end, the new cab suspension and new rear axle mounting, the truck is a joy to drive under all conditions.

DAF has pulled out all the stops in terms of efficiency to set a new benchmark.

Perfect visibility = safety

The relatively low seating position and the large windows with a low window beltline mean that the XD driver enjoys the best visibility in this class. The special ‘Vision Dashboard’ also plays an important role and extends towards the windscreen on the passenger side.

Cameras replace the mirrors on the optional DAF Digital Vision System, which provides an unsurpassed view of what is happening in front of and next to the truck. This is further enhanced by the option of adding the sublime DAF Corner Eye to replace the pavement and front view mirror. And for those who wish to ensure a perfect view and the highest level of safety, the DAF Kerb View Window is a must. This extra pane beneath the normal window on the passenger door means that cyclists and pedestrians at the side of the truck are always visible. The DAF City Turn Assist even sounds an alert when there are road users in the blind spot on the passenger side.

Tomorrow's efficiency

DAF achieves maximum fuel efficiency and low CO2 emissions primarily through the fantastic aerodynamics. Rounded edges, the curved windscreen, side walls at a subtle angle and seals wherever the wind could even slightly hamper the aerodynamics - DAF has pulled out all the stops to set a new benchmark for efficiency. This is also evident in the smart design and positioning of the exhaust gas treatment system and the new rear axles with low oil levels that result in even less internal friction. And an entirely logical step for DAF is the facilitation of a wide range of PTOs and ex factory options for quick and easy mounting of attachments.

After DAF astonished the transport world in 2021 with the New XF, XG and XG+ for long distances, it now knows that all eyes are on the New XD with which DAF is starting the future of the urban and regional distribution segment, special applications and last but not least, construction vehicles. It is a new winner in every sense of the word.

Jury chairman Gianenrico Griffini hands the trophy to Harald Seidel, president of DAF Trucks N.V.

DAF XD ‘International truck of the year 2023’

Last year, DAF won the title of International Truck of the Year 2022 with the ‘New Generation’ XF, XG and XG+. And this year at the IAA in Hanover DAF again won this prestigious award, this time with the XD, DAF’s premium newcomer in the distribution and vocational segment.

“DAF won last year because it was the first manufacturer to translate the new European regulations on vehicle dimensions into a range of long-haul trucks,” said jury chairman Gianenrico Griffini. “It’s amazing that they have now managed to inject a significant part of that same DNA into the XD, in terms of efficiency, safety and comfort. Whichever version of the XD you drive, as a driver it always feels like you are behind the wheel of an XG+; the silence, the driving behaviour, the quality, the all-round visibility, really unprecedented.”

Electric

The fact that the XD will also be immediately introduced as an electric truck was at least as important a reason for handing over the title to DAF. “This proves that DAF is ready for the future,” says Griffini. “DAF takes electric road transport a big step further in one go.”

XDC: Powerhouses for the construction sector

The XD range will be further expanded in early 2023 to include 2-, 3- and 4-axle models with single or double drive for the construction industry. This will allow the new XDC to provide a tailor-made solution for every application.

The ‘New Generation XDC’ can handle exceptionally high payloads, thanks to its low weight. The XDC range has been developed for heavy-duty work under the most demanding conditions, as evidenced by its extra robust bumper, steel protective radiator guard, extensive chassis clearance ranging from 300 to 390 millimetres (depending on the model) and the huge approach angle of 25 degrees. The bold grille, specially designed for this model, underlines the unique qualities of the new XDC.

The XDC is the ideal tool for drivers in the construction sector thanks to its perfect ergonomics, the large interiors of the day and sleeper cabs and the many details that will make a driver’s daily work even easier and more enjoyable. It provides the perfect combination of extreme functionality and unrivalled driver comfort.

For maximum efficiency, DAF offers a complete range of Body Attachment Modules (BAM) ex factory to make it easier to fit an attachment. These are naturally complemented with a comprehensive range of PTOs for powering attachments. The XDC also has options available for controlling attachments from the cab.